Stainless Steel 304l Seamless Pipe

- Home

- Stainless Steel 304l Seamless Pipe

Stainless Steel 304L Seamless Pipe is an austenitic stainless steel pipe with low carbon content and corrosion resistance. It is designed for leak-free and long-lasting performance under high pressure and temperature.

The grade meet ASTM A312 TP304L standards, making it ideal for applications that require strength, hygiene, and weldability. As a low-carbon variant of SS 304, it is very resistant to intergranular corrosion after welding. This make it suitable for welded structures such as tanks, pipelines, and vessels.

These pipes have smooth interior finish and seamless body make them useful in food processing, pharmaceutical, chemical, and marine industries. The non-reactive surface ensure hygiene and sturdy construction provide steady flow performance.

Neeka Tubes is a trusted 304L stainless steel pipe manufacturer in India, providing precision-made seamless pipes to both domestic and international customers. As a leading SS 304L pipe supplier in India, we offer cut-to-size solutions, schedule-customized dimensions, and certified products that meet global standards.

Best Deals, Guaranteed Quality! ASTM A304L Stainless Steel Seamless Tubing, ASTM A304LM Seamless Tubing, Stainless Steel 304L Seamless Tubing, and Stainless Steel Seamless Tubing in India!

What Is ASTM A312 TP304L Seamless Pipe?

ASTM A312 TP304L seamless pipe is a low-carbon stainless steel pipe engineered for strength, durability, and intergranular corrosion resistance. The ASTM A312 standard includes seamless stainless steel pipes used in high-pressure, high-temperature, and corrosive environments. This make this grade a dependable choice for demanding industries. The 304L stainless steel pipe contains no more than 0.03% carbon, which prevents carbide build-up and allows welding without post-weld heat treatment. Because the pipe is seamless, it offers uniform strength across the entire body, ensuring safe use in pressure systems and precision fluid transport. The UNS S30403 designation provide material consistency and full traceability. This seamless stainless steel pipe is fully compatible with the ASTM A312 and ASME SA312 standard which makes it appropriate for regulated industrial applications around the world.

Advantages of Stainless Steel 304l Seamless Pipe

- Good at Resisting Corrosion: Our Stainless Steel 304L seamless pipes resist rust, stains, and corrosion. They perform well in wet, humid, or mildly acidic environments. This makes them reliable for water systems, food processing, and chemical setups.

- Good Weldability: Our pipes are easy to weld and join without losing strength. Smooth welds form quickly, providing strong, secure connections that last over time in demanding applications.

- High Strength and Durability: 304L pipes are tough and long-lasting. They can withstand high pressure, stress, and wear, making them a dependable choice for industrial, commercial, and mechanical systems.

- Smooth Surface Finish: The pipes come with polished, even surfaces. Smooth walls improve fluid flow, reduce friction, and make cleaning and maintenance simpler and more effective.

- Easy Installation: Our pipes are lightweight and easy to handle. Cutting, fitting, and installing them is straightforward, which saves time and reduces labor during setup.

SS 304 vs SS 304L vs SS 316 – Seamless Pipe Grade Comparison

Choosing between SS 304 seamless pipe, SS 304L seamless pipe, and SS 316 seamless pipe depends on weldability, corrosion resistance, and the type of environment.

SS 304 Seamless Pipe: SS 304 is the standard stainless steel pipe grade. It has a balance of strength and corrosion resistance which makes it reliable for everyday industrial use. It is suitable for general piping jobs where welding is not the main focus.

SS 304L Seamless Pipe: SS 304L has less carbon than 304, which prevents intergranular corrosion after welding. This makes it a better fit for welded pressure vessels, tanks, and piping systems where joints face stress over time.

SS 316 Seamless Pipe: SS 316 pipe contain molybdenum which gives it superior resistance to chlorides, acids, and harsh chemicals. It is used for marine settings, chemical plants, and high-temperature service where other grades may fail.

Key Differences

304L offers easier weldability than 304.

316 handles salt, acids, and chemicals better than both 304 and 304L.

316 outperforms in marine, chemical, and heat-exposed piping.

Heat & Corrosion Resistance of SS 304L Pipe

SS 304L seamless pipe performs well in both hot and corrosive conditions. ASTM A312 TP304L pipe temperature rating reaches about 870°C for continuous service and up to 925°C for short cycles. The low carbon design protect pipe against intergranular corrosion after welding with no extra heat treatment is needed. This stability makes it a reliable heat resistant stainless steel pipe for boilers, steam lines, and thermal systems.

The 304L stainless steel pipe heat resistance helps it hold strength without warping or heavy scale build-up at high temperatures. These pipes resist oxidizing gases and mild acids present in chemical or hygienic processes. While not the best choice for high-chloride contact, like marine splash zones where 316 grades work better, it performs strongly in indoor, steam, and lightly corrosive settings. Its smooth surface and stainless steel 304L corrosion resistance also make it a safe choice for sanitary pipe systems in food and pharma lines.

Most Common Types of Stainless Steel 304l Seamless Pipe

SS 304l Seamless Pipe

304l SS Round Pipe

SS 304l Schedule 5S Pipe

SS 304l Polished Pipe

SS 304l Schedule 40 Seamless Pipe

304l Stainless Steel Thin Wall Pipe

Stainless Steel 304l Custom Pipe

Stainless Steel 304l Cold Drawn Seamless Pipe

Stainless Steel 304l Seamless Pipe Specifications

The specifications for SS 304L seamless pipes detail the size range, standards, and schedule options. This help buyers to select the appropriate pipe for their project requirements.

| Standard | AISI, DIN, EN, GB, JIS, ASTM, ASME |

| Pipe Dimensions | ANSI/ASME B36.19, B36.10 |

| Seamless Pipe OD | 6.00 mm OD up to 250 mm OD, Sizes up to 12” NB |

| Wall Thickness | 0.3mm – 50 mm |

| Available Sizes |

|

| Pipe Schedule | SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS |

| Finish & Surface Treatment | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish,etc |

| Form | Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

| Length | Single Random, Double Random, Standard & Cut length |

| End | Plain End, Beveled End, Treaded. |

| Manufacturing Technics | Seamless |

| Marking | All Pipes are marked as follows: Grade, Standard, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Testing Reports |

|

304l Stainless Steel Seamless Pipe Chemical Composition

The chemical makeup defines the corrosion resistance, weldability, and overall performance of the pipe. The following chart highlights the key alloy elements and their limits.

| Grade | C | Mn | Si | P | S | Cr | Ni |

| SS 304L | 0.08 max | 2 max | 1.00 max | 0.045 max | 0.030 max | 18 – 20 | 8 – 11 |

Mechanical Properties of SS 304l Seamless Pipe

Mechanical properties like tensile strength, hardness, and elongation show the durability of 304L stainless steel pipes in different industrial settings.

| Grade | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Equivalent Grades For 304l Stainless Steel Seamless Pipe

304L has various equivalent grades across international standards. This chart provides clarity for engineers and buyers who operate with global codes.

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304L | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18‐09 | X5CrNi18-10 |

Contact Neeka tubes today for a best offer & competitive quotation Of Stainless Steel 304l Seamless Pipes

Please Call on +91 7700067892 or drop an E-Mail : sales@neekatubes.net

Stainless Steel 304l Seamless Pipe Dimensions In MM

Dimension chart help in selecting pipes that fit project design. Standardized dimensions enable optimal alignment, strength, and flow performance.

| Nominal size in Inch | Outside diameter in Inch | Outside diameter in MM | Wall thickness in Inch | Wall thickness in MM | Weight [lb/ft] | Weight [kg/m] |

|---|---|---|---|---|---|---|

| 1/8 Inch | 0.405 | 10.3 MM | 0.068 | 1.73 | 0.24 | 0.37 |

| 1/4 Inch | 0.540 | 13.7 MM | 0.088 | 2.24 | 0.42 | 0.84 |

| 1/2 Inch | 0.840 | 21.3 MM | 0.109 | 2.77 | 0.85 | 1.27 |

| 3/4 Inch | 1.050 | 26.7 MM | 0.113 | 2.87 | 1.13 | 1.69 |

| 1 Inch | 1.315 | 33.4 MM | 0.133 | 3.38 | 1.68 | 2.50 |

| 1 1/4 Inch | 1.660 | 42.2 MM | 0.140 | 3.56 | 2.27 | 3.39 |

| 1 1/2 Inch | 1.900 | 48.3 MM | 0.145 | 3.68 | 2.72 | 4.05 |

| 2 Inch | 2.375 | 60.3 MM | 0.154 | 3.91 | 3.65 | 5.44 |

| 2 1/2 Inch | 2.875 | 73.0 MM | 0.203 | 5.16 | 5.79 | 8.63 |

| 3 Inch | 3.500 | 88.9 MM | 0.216 | 5.49 | 7.58 | 11.29 |

| 3 1/2 Inch | 4.000 | 101.6 MM | 0.226 | 5.74 | 9.11 | 13.57 |

| 4 Inch | 4.500 | 114.3 MM | 0.237 | 6.02 | 10.79 | 16.07 |

| 5 Inch | 5.563 | 141.3 MM | 0.258 | 6.55 | 14.62 | 21.77 |

| 6 Inch | 6.625 | 168.3 MM | 0.280 | 7.11 | 18.97 | 28.26 |

| 8 Inch | 8.625 | 219.1 MM | 0.322 | 8.18 | 28.55 | 42.55 |

| 10 Inch | 10.750 | 273.0 MM | 0.365 | 9.27 | 40.48 | 60.31 |

| 12 Inch | 12.750 | 323.8 MM | 0.406 | 10.31 | 53.52 | 79.73 |

| 14 Inch | 14 | 355.6 MM | 0.375 | 11.13 | 54.57 | 94.55 |

| 16 Inch | 16 | 406.4 MM | 0.500 | 12.70 | 82.77 | 123.30 |

| 18 Inch | 18 | 457.0 MM | 0.562 | 14.27 | 104.67 | 155.80 |

| 20 Inch | 20 | 508.0 MM | 0.594 | 15.09 | 123.11 | 183.42 |

| 24 Inch | 24 | 610.0 MM | 0.688 | 17.48 | 171.29 | 255.41 |

| 32 Inch | 32 | 813.0 MM | 0.688 | 17.48 | 230.08 | 342.91 |

Thickness Chart of SS 304l Seamless Pipe

The thickness chart shows the different wall thickness options for various schedules. This help to choose the appropriate strength level for pressure-based systems.

| Sizes | SCH 10 304 Grade Stainless Steel Pipe | O.D | |

| DIA | |||

| Inch | DN | Thickness | Millimetre (mm) |

| 1 Inch | DN 25 | 2.77 | 33.4 |

| 2 Inch | DN 50 | 2.77 | 60.3 |

| 3 Inch | DN 80 | 3.05 | 88.9 |

| 4 Inch | DN 100 | 3.05 | 114.3 |

| 5 Inch | DN 125 | 3.43 | 141.3 |

| 6 Inch | DN 150 | 3.43 | 168.3 |

| 8 Inch | DN 200 | 3.76 | 219.1 |

| 10 Inch | DN 250 | 4.19 | 273.1 |

| 11/2 Inch | DN 40 | 2.77 | 48.3 |

| 11/4 Inch | DN 32 | 2.77 | 24.2 |

| 12 Inch | DN 300 | 4.57 | 323.9 |

| 14 Inch | DN 350 | 6.35 | 355.6 |

| 16 Inch | DN 400 | 6.35 | 406.4 |

| 18 Inch | DN 450 | 6.35 | 457.2 |

| 21/2 Inch | DN 65 | 3.05 | 73 |

| 22 Inch | DN 550 | 6.35 | 558.8 |

| 24 Inch | DN 600 | 6.35 | 609.6 |

| 34 Inch | DN 850 | 7.92 | 863.6 |

| 31/2 Inch | DN 90 | 3.05 | 101.6 |

| 36 Inch | DN 900 | 7.92 | 914.4 |

304L Seamless Pipe Price per Kg in India (₹/kg)

The 304L seamless pipe price per kg in India is based on size, schedule, surface finish, and mill origin. On average it ranges between ₹280/kg to ₹500/kg. Factors like wall thickness, annealed or pickled finish, and standards also affect cost. Price fluctuate with nickel rates, import duties, and stock levels. We provide a stainless steel 304L pipe price chart with detailed sizes and rates for clarity.

Testing & Certifications for SS 304L Seamless Pipe

Every SS 304L seamless pipe go through testing before dispatch. Hydrostatic testing checks pressure strength to ensure leak-free performance. Non-destructive testing stainless steel pipe methods like ultrasonic or eddy current, spot hidden cracks or voids without harming the pipe. Positive Material Identification (PMI) confirms the right grade and chemical makeup. Mechanical tests such as tensile, hardness and flattening guarantee strength and durability in real service. Each order comes with EN 10204 3.1 MTC as proof of quality. For added assurance, ASTM A312 TP304L certification pipes can be verified by third-party inspection stainless pipe agencies like SGS, TUV, or BV. This process ensures quality and reliability.

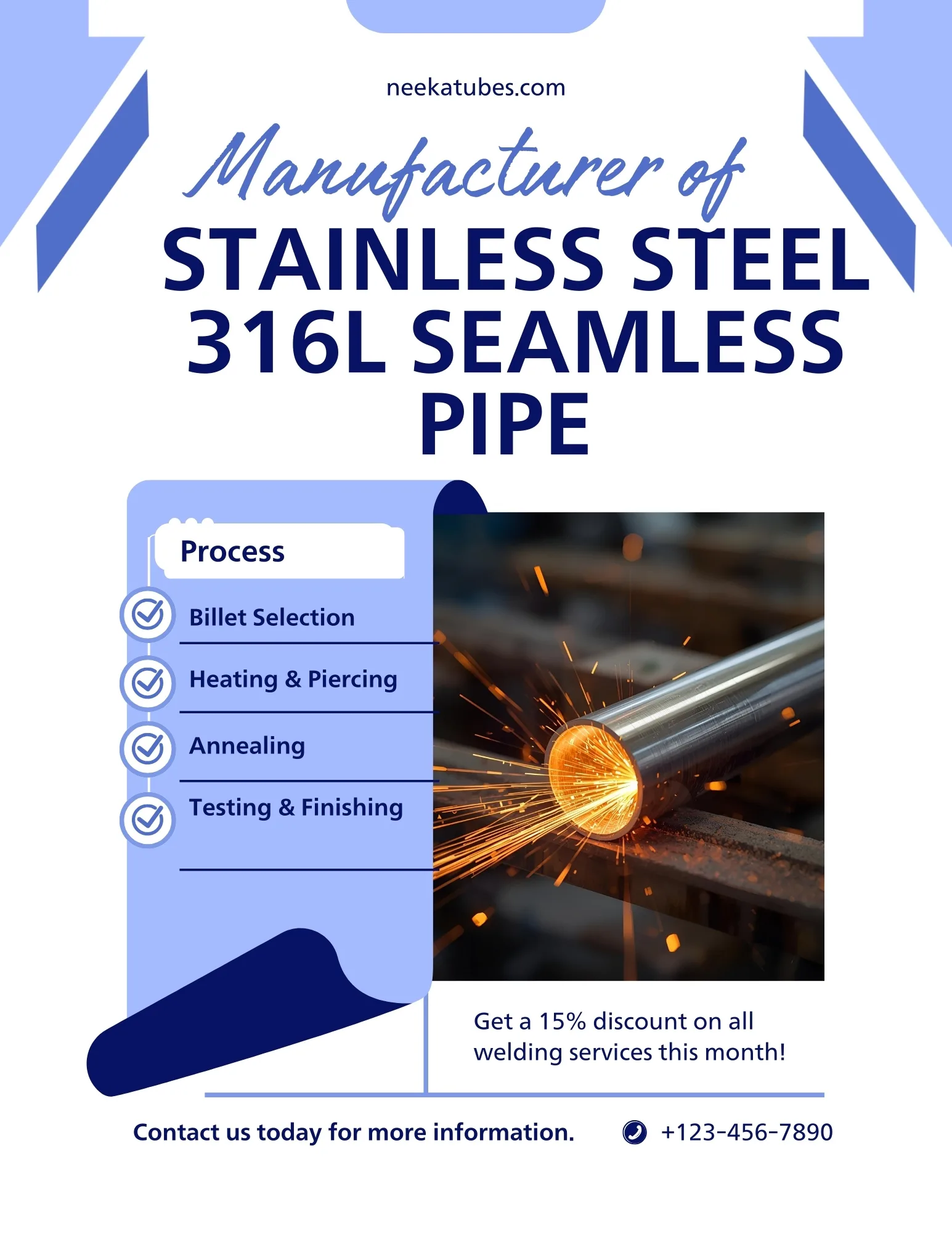

Manufacturing Process for SS 316L Seamless Pipe

SS 304L seamless pipes are made through a controlled hot-working process that ensure a weld-free body.

- Billet Selection: Solid low-carbon stainless steel billets are chosen.

- Heating & Piercing: Billets are heated and pierced to form a hollow shell.

- Elongation & Sizing: The shell is lengthened and sized with mandrel or plug mills.

- Annealing: Heat treatment restore ductility and corrosion resistance.

- Pickling & Surface Finish: Acid pickling clean the surface for a smooth finish.

- Testing & Finishing: Pipes are straightened, cut, and tested as per ASTM A312 TP304L standards.

This SS 304L seamless pipe manufacturing process ensure pipes meet industry needs for hygiene and pressure service.

Packaging & Delivery of SS 304L Pipes – Export & Domestic

We do proper SS 304L seamless pipe packaging to maintain quality during transport and storage. Each pipe has plastic end caps to protect the edges and covered in waterproof material to prevent moisture and corrosion. Pipes for export are packed in ISPM-15 certified wooden crates to ensure global compliance and secure handling. Clear labeling with batch number, size, and heat number make every pipe traceable. Our stock pipes reach faster, while custom sizes take more time. With strong packing standards and efficient pipe logistics, both domestic and international customers receive safe and on-time delivery.

Why Choose Neeka Tubes for SS 304L Pipes

Neeka Tubes is a trusted SS 304L pipe manufacturer in India with global reach.

- Specialization in ASTM A312 TP304L: We concentrate on ASTM A312 TP304L pipes and conduct rigorous quality inspections at all stages.

- Wide Range & Custom Sizes: Pipes are available in many sizes with option for custom lengths to match project needs.

- Ready Stock Availability: Large inventory ensure quick dispatch for urgent requirements without long lead times.

- Third-Party Inspection & Certification: Pipes come with EN 10204 3.1 certification and third-party inspection support.

- Export-Grade Packaging: We follow ISPM-15 export pipe packing standards to protect pipes during international shipping.

- Technical Support & Partnerships: Our team provide expert advice and develop long-term, dependable relationship with clients.

- Global Export Assurance: As a 304L seamless pipe exporter, we deliver certified, cost-effective, and dependable products worldwide.

Searching for Ready Stock of Stainless Steel 304l Seamless Pipes in Mumbai?

Applications of SS 304L Seamless Pipes

SS 304L seamless pipe applications are as follows:

- Food & Beverage Processing Lines – Smooth, non-reactive pipes for sanitary systems.

- Pharmaceutical Manufacturing – Cleanroom pipes and sterile flow systems.

- Chemical & Petrochemical – Handle acids, solvents, and corrosive fluids.

- Water Treatment & Desalination – Performs in purification and saltwater environments.

- Oil & Gas Pipelines – Withstand pressure and corrosive service.

- Architectural & Structural – These pipes provide strength and aesthetics in building projects.

FAQ - Stainless Steel 304L Seamless Pipe

What is ASTM A312 TP304L and how is it different from regular SS 304 pipes?

ASTM A312 TP304L is a low-carbon seamless stainless steel pipe. Unlike SS 304, it reduces carbide precipitation which make it safe for welding.

: Are SS 304L seamless pipes suitable for pressure-based systems?

The seamless design provide uniform strength and reliability in high-pressure applications.

What sizes and schedules are available in SS 304L seamless pipes?

They are available in various sizes and schedules from thin-wall tubing to heavy-duty industrial grades.

: Is international shipping available for SS 304L seamless pipes?

Neeka Tubes ships worldwide with export-grade packaging and timely delivery.

- Pipes

- Stainless Steel Pipes

- Titanium Pipes

- Tubing

- Sheets and Plates

- Fasteners

- Pipe Fittings

- Round Bar

- Hex Bars

- Square Bars

- Wire

- Flanges

- Other Fittings

- Springs

Request For Quotation

About Neeka Tubes

Quick Contact

Mumbai - 400004