Table of Content

- Most Common Types of SS Seamless Pipe

- SS Seamless Pipe Specifications

- SS Seamless Pipe Dimensions Chart

- SS Seamless Pipe Thickness Chart

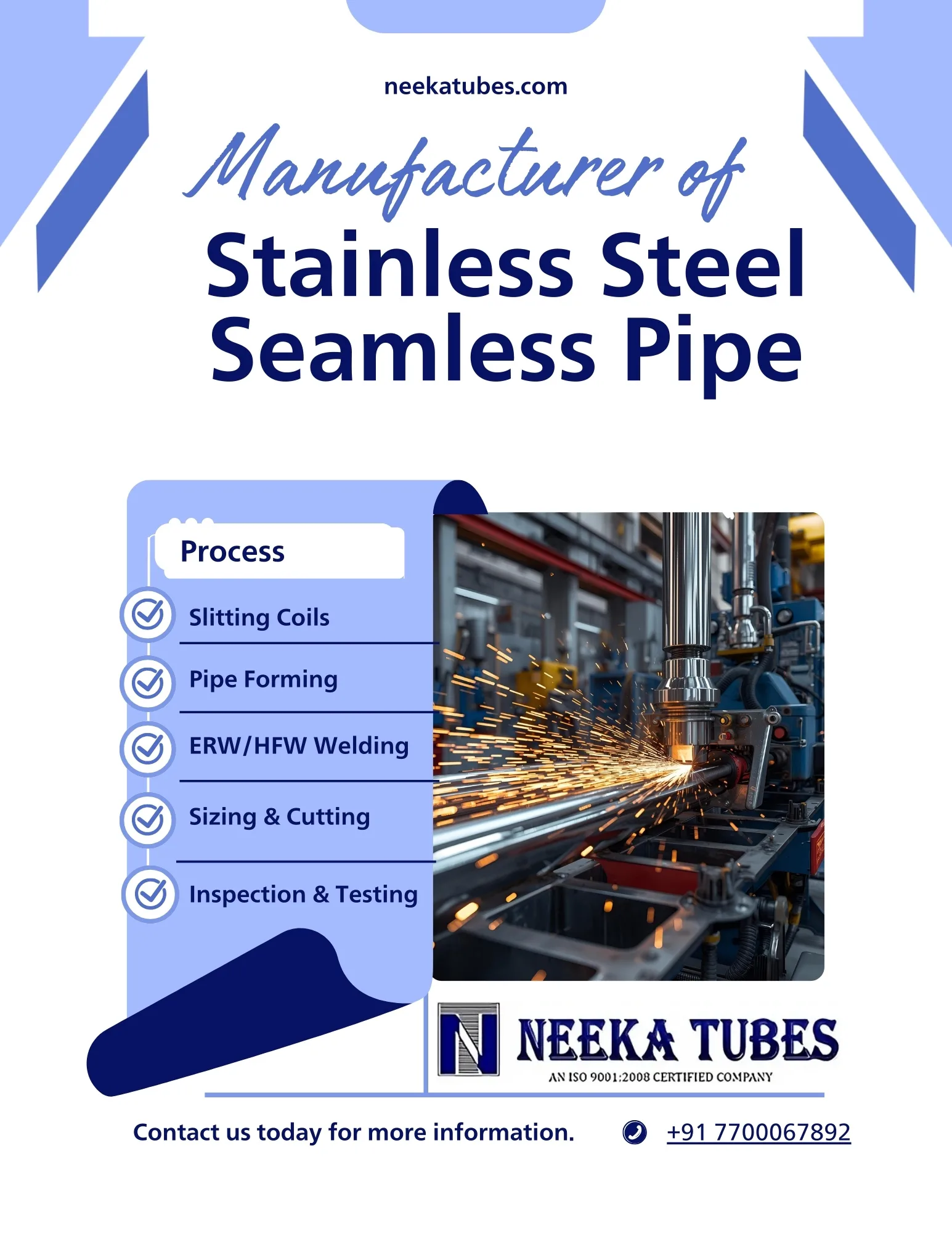

- Stainless Steel Seamless Pipe Manufacturing Process

- SS Seamless Pipe Packing & Marking

- Why Choose Neeka Tubes for SS Seamless Pipes?

- Application of SS Seamless Pipe

- Frequently Asked Questions – Stainless Steel Seamless Pipe

Neeka Tubes is a trusted stainless steel pipe manufacturer known for delivering high-quality, seamless stainless steel pipes for demanding industrial applications. As one of the leading SS seamless pipe manufacturers in India, we offer a wide range of sizes and grades designed to meet global standards like ASTM A312 and ASME SA312. Our pipes are strong, resistant to corrosion, and precise, which makes them perfect for industries like oil and gas, petrochemicals, power, and more. Backed by experience and reliable service, we stand out as a dependable SS seamless pipe supplier with the capability to meet both domestic and international needs. Whether you require seamless stainless steel tubes in bulk quantities or specialized sizes, our team is available to help you complete your project with consistent quality and timely delivery.

Stainless Steel Seamless Pipe, SS Seamless Pipe, Seamless Steel Pipe, SS Seamless Pipe, SS Seamless Pipe, Industrial SS Pipes, High-Quality Stainless Steel Pipes, ASTM A312 Stainless Steel Seamless Pipe, SS Seamless Pipe HSN Code

- Pipes

- Stainless Steel Pipes

- Titanium Pipes

- Tubing

- Sheets and Plates

- Fasteners

- Pipe Fittings

- Round Bar

- Hex Bars

- Square Bars

- Wire

- Flanges

- Other Fittings

- Springs

Request For Quotation

What are Stainless Steel Seamless Pipes?

Stainless steel seamless pipes are made without any welds, giving them a strong and uniform structure. They provide leak-proof performance, making them excellent for high-pressure, high-temperature applications. Known for their excellent corrosion resistance, these pipes are a reliable choice for tough environments. SS 304 seamless pipe, SS 316, and SS 321 are commonly utilized in industrial and commercial environments. The seamless pipes are manufactured in accordance with global standards such as ASTM A312, ASTM A213, and DIN 17456. As reliable seamless tube manufacturers, we provide pipes that play vital roles in the petrochemical, marine, power generation, and pharmaceutical industries. High-pressure SS pipe is offered in SCH 10 to SCH 160, with sizes ranging from 1/8″ NB to 24″ NB to meet a variety of project requirements.

Key Features of Stainless Steel Seamless Pipes

Stainless steel seamless pipes are known for their strength, precision, and durability in tough working conditions. From industrial plants to cleanroom environments, they deliver dependable performance where it matters most.

- No welds – higher pressure tolerance

Seamless steel pipe is formed without welding, eliminating weak spots. This allows it to handle high pressure with confidence. - Smooth internal surface for efficient flow

The inside surface is smooth and clean, which makes it easier for fluids and gases to circulate without getting stuck or building up. It keeps the system working well. - Excellent resistance to corrosion and oxidation

Whether exposed to moisture, acids or air, these pipes, especially SS 304 seamless pipe, stand strong without rusting or degrading. - Withstands high temperatures and harsh chemicals

Made for extreme environments, high-pressure stainless steel pipe performs well in hot, corrosive or chemically loaded systems. - Uniform thickness and dimensional accuracy

Every pipe is produced with precise measurements, ensuring a perfect fit and steady flow across applications. - Longer lifespan with low maintenance

Corrosion-resistant pipe lasts for years without the need for constant upkeep, saving both time and cost. - Ideal for high-pressure, high-stress applications

Seamless pipes are used in important systems such as oil refineries, power plants and chemical plants where performance must be maintained. - Clean finish – suitable for hygienic use

With a smooth, non-reactive surface, they are safe for food, pharma, and clean water systems.

Most Common Types of Stainless Steel Seamless Pipe

SS Seamless Pipe

SS Seamless Round Pipe

SS Seamless 5S Pipe

SS Polished Seamless Pipe

SS Schedule 40 Seamless Pipe

SS Seamless Thin Wall Pipe

Stainless Steel Seamless Custom Pipe

Stainless Steel 310 Cold Drawn Seamless Pipe

Stainless Steel Seamless Pipe Specifications

This section discusses the major features of stainless steel seamless pipes, such as material grades, standards, schedules, and available sizes. It helps you in selecting the appropriate pipe based on technical and application requirements.

| Range : | 6NB to 1200NB |

| Outer Diameter : | 1/8″ NPS to 12″ NPS |

| Thickness : | 0.6 mm to 12.7 mm |

| Schedules : | SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS. |

| Length : | Single Random, Double Random & Cut Length |

| Specifications : | ASTM A312 / ASTM SA312 |

| Types : | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| End : | Plain End, Beveled End |

Contact Neeka tubes today for a best offer & competitive quotation Of Stainless Steel Seamless Pipes

Please Call on +91 7700067892 or drop an E-Mail : sales@neekatubes.net

Stainless Steel Seamless Pipe Dimensions in MM

The standard outer diameters of SS seamless pipes are listed in millimeters. This table makes it easy to choose the correct pipe size for your project.

| Stainless Steel Seamless Pipe OD mm | Pipe WT mm | in. | Sch | Kg/m |

|---|---|---|---|---|

| 13.72 | 1.65 | 1/4 | 10S | 0.50 |

| 13.72 | 2.24 | 1/4 | 40S | 0.64 |

| 13.72 | 3.02 | 1/4 | 80S | 0.81 |

| 17.15 | 1.65 | 3/8 | 10S | 0.64 |

| 17.15 | 2.31 | 3/8 | 40S | 0.86 |

| 17.15 | 3.20 | 3/8 | 80S | 1.12 |

| 21.34 | 2.11 | 1/2 | 10S | 1.02 |

| 21.34 | 2.77 | 1/2 | 40S | 1.29 |

| 21.34 | 3.73 | 1/2 | 80S | 1.65 |

| 26.67 | 2.11 | 3/4 | 10S | 1.30 |

| 26.67 | 2.87 | 3/4 | 40S | 1.71 |

| 26.67 | 3.91 | 3/4 | 80S | 2.23 |

| 33.40 | 2.77 | 1 | 10S | 2.13 |

| 33.40 | 3.38 | 1 | 40S | 2.54 |

| 33.40 | 4.55 | 1 | 80S | 3.29 |

| 33.40 | 6.352) | 1 | 160 | 4.30 |

| 42.16 | 2.77 | 1¼ | 10S | 2.73 |

| 42.16 | 3.56 | 1¼ | 40S | 3.44 |

| 42.16 | 4.85 | 1¼ | 80S | 4.53 |

| 42.16 | 6.352) | 1¼ | 160 | 5.69 |

| 48.26 | 2.77 | 1½ | 10S | 3.16 |

| 48.26 | 3.68 | 1½ | 40S | 4.11 |

| 48.26 | 5.08 | 1½ | 80S | 5.49 |

| 60.33 | 2.77 | 2 | 10S | 3.99 |

| 60.33 | 3.91 | 2 | 40S | 5.52 |

| 60.33 | 5.54 | 2 | 80S | 7.60 |

| 60.33 | 8.742) | 2 | 160 | 11.29 |

| 73.03 | 3.05 | 2½ | 10S | 5.35 |

| 73.03 | 5.16 | 2½ | 40S | 8.77 |

| 73.03 | 7.01 | 2½ | 80S | 11.59 |

| 88.90 | 3.05 | 3 | 10S | 6.56 |

| 88.90 | 5.49 | 3 | 40S | 11.47 |

| 88.90 | 7.62 | 3 | 80S | 15.51 |

| 88.90 | 11.132) | 3 | 160 | 21.67 |

| 101.60 | 3.05 | 3½ | 10S | 7.53 |

| 101.60 | 5.74 | 3½ | 40S | 13.78 |

| 101.60 | 8.08 | 3½ | 80S | 18.92 |

| 114.30 | 3.05 | 4 | 10S | 8.50 |

| 114.30 | 6.02 | 4 | 40S | 16.32 |

| 114.30 | 8.56 | 4 | 80S | 22.67 |

| 114.30 | 13.492) | 4 | 160 | 34.05 |

| 141.30 | 6.55 | 5 | 40S | 22.10 |

| 141.30 | 9.53 | 5 | 80S | 31.44 |

| 141.30 | 15.882) | 5 | 160 | 49.87 |

| 168.28 | 3.4 | 6 | 10S | 14.04 |

| 168.28 | 7.11 | 6 | 40S | 28.69 |

| 168.28 | 10.97 | 6 | 80S | 43.21 |

| 168.28 | 14.27 | 6 | 120 | 54.75 |

| 168.28 | 18.262) | 6 | 160 | 68.59 |

| 219.08 | 8.18 | 8 | 40S | 43.20 |

| 219.08 | 12.7 | 8 | 80S | 65.63 |

| 219.08 | 18.23 | 8 | 120 | 91.30 |

| 219.08 | 23.012) | 8 | 160 | 112.97 |

SS Seamless Pipe Thickness Chart

This chart shows the wall thickness for various pipe schedules, helping you match strength and pressure requirements with the right pipe dimensions.

| Nominal size [inches] | Outside diameter [inches] | Outside diameter [mm] | Wall thickness [inches] | Wall thickness [mm] | Weight [lb/ft] | Weight [kg/m] |

| 1/8 | 0.405 | 10.3 | 0.095 | 2.41 | 0.31 | 0.47 |

| 1/4 | 0.54 | 13.7 | 0.119 | 3.02 | 0.54 | 0.8 |

| 1/2 | 0.84 | 21.3 | 0.147 | 3.73 | 1.09 | 1.62 |

| 3/4 | 1.05 | 26.7 | 0.154 | 3.91 | 1.47 | 2.2 |

| 1 | 1.315 | 33.4 | 0.179 | 4.55 | 2.17 | 3.24 |

| 1 1/4 | 1.66 | 42.2 | 0.191 | 4.85 | 3 | 4.47 |

| 1 1/2 | 1.9 | 48.3 | 0.2 | 5.08 | 3.63 | 5.41 |

| 2 | 2.375 | 60.3 | 0.218 | 5.54 | 5.02 | 7.48 |

| 2 1/2 | 2.875 | 73 | 0.276 | 7.01 | 7.66 | 11.41 |

| 3 | 3.5 | 88.9 | 0.3 | 7.62 | 10.25 | 15.27 |

| 3 1/2 | 4 | 101.6 | 0.318 | 8.08 | 12.5 | 18.63 |

| 4 | 4.5 | 114.3 | 0.337 | 8.56 | 14.98 | 22.32 |

| 5 | 5.563 | 141.3 | 0.375 | 9.53 | 20.78 | 30.97 |

| 6 | 6.625 | 168.3 | 0.432 | 10.97 | 28.57 | 42.56 |

| 8 | 8.625 | 219.1 | 0.5 | 12.7 | 43.39 | 64.64 |

| 10 | 10.75 | 273 | 0.594 | 15.09 | 64.43 | 96.01 |

| 12 | 12.75 | 323.8 | 0.688 | 17.48 | 88.63 | 132.08 |

| 14 | 14 | 355.6 | 0.75 | 19.05 | 106.13 | 158.1 |

| 16 | 16 | 406.4 | 0.844 | 21.44 | 136.61 | 203.53 |

| 18 | 18 | 457 | 0.938 | 23.83 | 170.92 | 254.55 |

| 20 | 20 | 508 | 1.031 | 26.19 | 208.87 | 311.17 |

| 24 | 24 | 610 | 1.125 | 30.96 | 296.58 | 442.08 |

Stainless Steel Seamless Pipe Manufacturing Process

The manufacturing process of SS seamless pipes involves precise techniques to ensure high strength, uniformity, and performance under pressure.

- Selection of high-quality stainless steel billets

The procedure starts with solid stainless steel billets. These billets are free of cracks and impurities, which ensures consistent pipe quality. - Heating billets in a rotary furnace

The billets are heated to high temperatures in a rotary furnace. This softens the metal, making it easier to shape. - Hot piercing to create a hollow shell

A piercing machine pushes a rod through a hot billet. This results in a hollow tube with no welding or joints. - Rolling and elongation to desired size

The hollow shell passes through rolling mills. It is stretched and shaped to achieve the desired diameter and wall thickness. - Heat treatment to improve mechanical properties

Pipes are heat-treated in a controlled environment. This strengthens the metal and relieves internal stress. - Pickling and passivation for surface finish

The pipes are cleaned with acid to remove scale. Passivation then forms a protective layer that boosts corrosion resistance. - Cold drawing (if required) for dimensional accuracy

If tighter tolerances are needed, pipes go through cold drawing. This step improves surface finish and ensures uniform size. - Final testing, inspection, and marking before dispatch

Every pipe is tested for strength, size, and surface quality. After passing inspection, it’s marked and packed for delivery.

Packaging & Delivery of SS Seamless Pipes

We follow secure pipe packaging methods to protect every order during transit. Each stainless steel pipe is fitted with plastic end caps, covered in plastic film, and tightly bundled to prevent surface damage. We utilize strong hardwood boxes or crates to pack SS pipe for overseas shipping. Every bundle comes with clear labels and product markings for easy tracking. We follow all customer guidelines and export standards while preparing the shipment. Whether it’s a small batch or a large order, we handle seamless pipe shipping through trusted logistics partners to ensure on-time delivery. Our team handles urgent deliveries without delay. When it comes to the packaging of SS seamless pipes, we take every step to keep them safe and delivery-ready.

SS Seamless Pipe Testing & Certifications

Every SS seamless pipe goes through strict quality checks to confirm material identity and inner strength. We carry out PMI, hydrostatic and ultrasonic tests as part of standard SS seamless pipe testing. On request, we also perform radiography and full mechanical evaluations. All certified SS seamless pipes follow global standards like EN 10204 3.1 and 3.2. We offer third-party inspection through trusted agencies to meet customer needs. Our seamless pipe quality tests are backed by full traceability and proper records. WE operate under ISO 9001:2015 to ensure consistent quality and trusted stainless steel pipe certifications.

Why Choose Neeka Tubes for SS Seamless Pipes?

Neeka Tubes stands out as a reliable stainless steel seamless pipe supplier with a strong focus on quality, service, and timely delivery.

- ISO 9001:2015 certified seamless pipe manufacturer

We follow a certified quality system to make sure every pipe meets high standards. - Wide stock of SS 304, 316, and 321 seamless pipes

Our ready stock includes popular SS seamless pipes in different grades and sizes. - Fast delivery and strong supply chain support

We ship quickly using a reliable network that keeps orders moving without delays. - Export-ready with global delivery capabilities

As a trusted SS pipe exporter, we handle global orders with proper export packing and documents. - Competitive pricing and flexible order quantities

We offer fair prices and accept both small and bulk orders to suit customer needs. - Stringent quality checks and third-party testing

Every pipe goes through tests, and we also arrange third-party inspection when needed. - Experienced team and technical assistance

Our skilled team assists customers with product selection and provides support at all stages. - Customized sizing and value-added services

We offer cut-to-length pipes, surface finish options, and other custom services for specific applications.

Searching for ready stock of Stainless Steel Seamless Pipes in Mumbai?

Applications of SS Seamless Pipes

Stainless steel seamless pipes are utilized in industries that require high strength, dependability and corrosion resistance. Their broad application range makes them a reliable alternative for fluid transmission, structural applications and high-temperature situations.

- Oil & Gas

Seamless steel pipe in oil and gas is essential for pipelines, drilling operations, and high-pressure refinery systems. It handles extreme conditions without cracking or leaking. - Petrochemical

These pipes carry aggressive chemicals in processing lines and feed systems. Their corrosion resistance keeps operations safe and consistent. - Power Generation

Seamless pipes for high temperatures are used in boilers, condensers and heat exchangers. They perform reliably under thermal stress and pressure. - Pharmaceutical

In sterile production zones, it is used in applications that include clean transport lines that help maintain purity and prevent contamination. - Food & Beverage

SS seamless pipes form the backbone of clean-in-place (CIP) and steam-in-place (SIP) setups. They support hygienic and corrosion-free flow systems. - Marine

These pipes are built to resist seawater corrosion, making them ideal for shipbuilding, offshore rigs, and underwater piping networks. - Automotive

Industrial stainless steel pipes are used in exhaust lines, fuel injection systems, and hydraulic tubing. They can withstand high temperatures and vibration without fail. - Construction

Strong and durable, stainless steel pipes support structural frameworks, firefighting lines, and pressure-bearing installations in modern buildings. - Water Treatment

Seamless pipes in desalination and RO systems ensure that water flows smoothly and rust-free, even in harsh environments. - Aerospace

In aircraft systems, corrosion resistant pipe uses include high-pressure fuel and hydraulic lines where weight, safety, and strength all matter.

Frequently Asked Questions – Stainless Steel Seamless Pipe

What is the difference between seamless and welded stainless steel pipes?

Seamless pipes are manufactured without any welding, offering higher strength and uniformity. Welded pipes are made by joining steel plates and may have a visible seam.

What is the standard size range for SS seamless pipes?

SS seamless pipes are typically 1/8″ to 24″ in diameter, with various wall thicknesses depending on the application.

Can stainless steel seamless pipes be used for high-temperature applications?

Yes, they are ideal for high-temperature and high-pressure environments due to their excellent heat resistance and structural integrity.

Do SS seamless pipes require special packaging?

Yes, they are usually packed in wooden boxes, plastic caps, or wrapped in waterproof material to prevent surface damage and contamination during transit.

Which grades are commonly available in stainless steel seamless pipes?

Common grades include 304, 304L, 316, 316L, 321, and 310S, each suited for different corrosion and temperature resistance requirements.

About Neeka Tubes

Quick Contact

Mumbai - 400004