Copyright © 2024 Neeka Tubes All Rights Reserved. | Created & SEO by RATH INFOTECH

Carbon Steel Pipe Fittings

- Home

- Carbon Steel Pipe Fittings

Neeka Tubes is a trusted manufacturer and supplier of carbon steel pipe fittings. They provide good-quality products around the world. Carbon steel pipe fittings are parts used in piping systems to connect, redirect, or control the flow of liquids. These fittings have great strength and last a long time. They can also handle high temperatures and pressures. Our pipe fittings are essential for connecting, controlling and directing fluid flow in pipelines. Manufactured per industry standards ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 and is available in seamless, welded and fabricated types.

Our carbon steel pipe fittings undergo strict manufacturing processes, ensuring durability and precision. The process includes cutting, heating, shaping and finishing to meet ASTM A234 / ASME SA234 specifications. We supply a full range of carbon steel buttweld fittings, including reducers, elbows, tees, crosses, stub ends and pipe bends.

Table of Content

- Most Common Types of Carbon Steel Pipe Fittings

- Carbon Steel Pipe Fittings Specifications

- Carbon Steel Pipe Fittings Properties

- Carbon Steel Pipe Fittings Dimensions Chart

- Carbon Steel Pipe Fittings Weight Chart

- Carbon Steel Pipe Fittings Packing & Marking

- Industrial Application of Carbon Steel Pipe Fittings

Check Availability of Carbon Steel Pipe Fittings, Best Quality Carbon Steel Pipe Fittings,, We stock a range of CS Pipe Fittings Manufacturers in India.

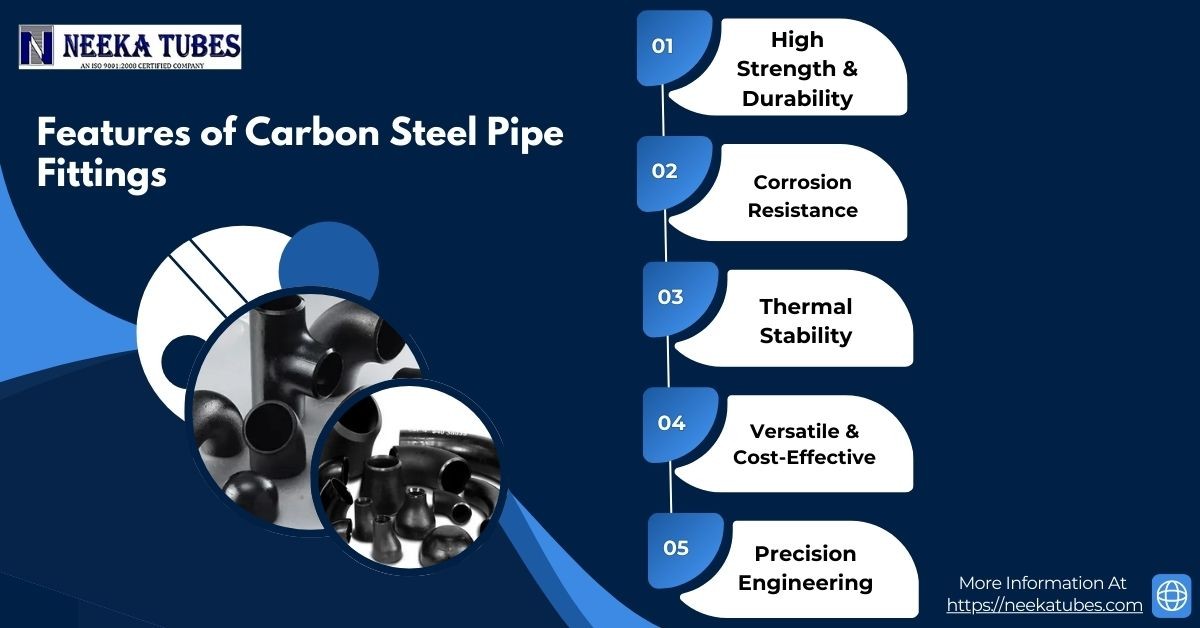

Features of Carbon Steel Pipe Fittings

- High Strength & Durability – Provides good strength against stress and pressure.

- Corrosion Resistance – Special coatings help improve how long things last in tough places.

- Thermal Stability – These fittings have a density of 7.85 g/cm³ and melt at 1425-1540°C. They work well in high temperatures.

- Versatile & Cost-Effective – Are used in many industries and is easy on the budget.

- Precision Engineering – Precision Engineering is made to follow global standards. It has strict quality checks.

As a top supplier of carbon steel pipe fittings, our products are used in different industries. These include the chemical industry, oil refineries, textile industry, nuclear power plants, shipyards, and fabrication companies. Our fittings ensure seamless fluid transport, withstand high-pressure and high-temperature conditions and play a crucial role in structural applications.

Most Common Types of Carbon Steel Pipe Fittings

Carbon Steel Buttweld Elbow

Carbon Steel Buttweld Tee

Carbon Steel Cross

Carbon Steel Pipe Cap

Carbon Steel Reducer

Carbon Steel Stub End

Carbon Steel Pipe Bend

Carbon Steel Pipe Nipples

Carbon Steel Pipe Fittings Specifications

| Standards | ASTM A234 / ASME SA234 |

| Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| Size | Seamless Butt Weld Fittings : 1/2″ – 10″ Welded Butt Weld Fittings : 1/2″ – 48″ |

| Type | Seamless / Welded / Fabricated |

| Schedule | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom |

| Form | 90 Elbow, 45 Elbow, Long Radius Elbow’ Short Radius Elbow, Concentric Reducer, Eccentric Reducer, Equal Tee, Unequal Tee, Lateral Tee, Cross, Bends 1.5d, 3d, 5d, 10d, U bend, 180 Deg Bend, Short Stub End, Long stub end, Concentric Reducer,End Cap, Dish Cap, Lap-joint Stub End |

Carbon Steel Pipe Fittings, Best Quality ASTM A234 CS Pipe Fittings,, We stock a range of CS Pipe Fittings Manufacturers in India.

Carbon Steel Pipe Fittings Chemical Composition

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A234 WPB | 0.3 | 0.60-1.35 | 0.15-0.30 | 0.04 | 0.035 | 0.3 | 0.12 |

Mechanical Properties of Carbon Steel Pipe Fittings

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) |

| A234 WPB | 60-85[415-585] | 35[240] |

Equivalent Grades For Carbon Steel Pipe Fittings

| STANDARD | WERKSTOFF NR. | UNS |

| CS Pipe Fitting | 1.4301 | S30400 |

Contact Neeka tubes today for a best offer & competitive quotation Of Carbon Steel Buttweld Pipe FittingsPlease Call on +91 7700067892 or drop an E-Mail : sales@neekatubes.net

Carbon Steel Pipe Fittings Dimensional Tolerances

| All Fittings[Note(1) and (2)] | Center-to-End Diamensions | Overall Length of Reducers and Lap Joint Stub Ends,F,H | Overall Length of Caps, E | 180-deg Returns | ||||||

| Nominal Pipe Size(NPS) | DN | Outside Diameter at Bevel,D[Note(3) and (4)] | Inside Diameter at End [Note(3) and (5)] | 90-deg and 45-deg Long and Short Radius Elbows and Tees. A,B,C,M | 3D Radius Elbows, A,B | Center-to-Center Dimension, O | Back-to-Face Demensoin, K | Alignment of Ends, U | ||

| 1/2to2 1/2 | 15-65 | +1.6-0.8 | 0.8 | 2 | 3 | 2 | 3 | 6 | 6 | 1 |

| 3to3 1/2 | 80-90 | 1.6 | 1.6 | 2 | 3 | 2 | 3 | 6 | 6 | 1 |

| 4 | 100 | 1.6 | 1.6 | 2 | 3 | 2 | 3 | 6 | 6 | 1 |

| 5to8 | 125-200 | +2.4 -1.6 | 1.6 | 2 | 3 | 2 | 6 | 6 | 6 | 1 |

| 10to18 | 250-450 | +4.0 -3.2 | 3.2 | 2 | 3 | 2 | 6 | 10 | 6 | 2 |

| 20to24 | 500-800 | +6.4 -4.8 | 4.8 | 2 | 3 | 2 | 6 | 10 | 6 | 2 |

| 26to30 | 650-750 | +6.4 -4.8 | 4.8 | 3 | 6 | 5 | 10 | … | … | … |

| 32to48 | 800-1200 | +6.4 -4.8 | 4.8 | 5 | 6 | 5 | 10 | … | … | … |

| All Fittings[Note(1) and (2)] | Center-to-End Diamensions | Nominal Pipe Size(NPS) | DN | Angularity Tolerance | ||||||

| Nominal Pipe Size(NPS) | DN | Outside Diameter at Bevel,D[Note(3) and (4)] | Inside Diameter at End [Note(3) and (5)] | Outside Diameter of Lap,G | Fillet Radius of Lap,R | Lap Thickness | Off Angle,Q | Off Plane,P | ||

| 1/2to2 1/2 | 15-65 | +1.6-0.8 | 0.8 | +0,-1 | +0,-1 | +1.6,-0 | 1/2to4 | 15-100 | 1 | 2 |

| 3to3 1/2 | 80-90 | 1.6 | 1.6 | +0,-1 | +0,-1 | +1.6,-0 | 5to8 | 125-200 | 2 | 4 |

| 4 | 100 | 1.6 | 1.6 | +0,-1 | +0,-2 | +1.6,-0 | 10to12 | 250-300 | 3 | 5 |

| 5to8 | 125-200 | +2.4 -1.6 | 1.6 | +0,-1 | +0,-2 | +1.6,-0 | 14to16 | 350-400 | 3 | 6 |

| 10to18 | 250-450 | +4.0 -3.2 | 3.2 | +0,-2 | +0,-2 | +3.2,-0 | 18to24 | 450-800 | 4 | `10 |

| 20to24 | 500-800 | +6.4 -4.8 | 4.8 | +0,-2 | +0,-2 | +3.2,-0 | 26to30 | 650-750 | 5 | 10 |

| 26to30 | 650-750 | +6.4 -4.8 | 4.8 | … | … | … | 32to42 | 800-1050 | 5 | 13 |

| 32to48 | 800-1200 | +6.4 -4.8 | 4.8 | … | … | … | 44to48 | 1100-1200 | 5 | 19 |

Carbon Steel Pipe Fittings Pressure Rating

| W.T. (in) (mm) | Pipe SCH | Pipe Size (inches) | Temperature (oF) (deg C) | O.D. (in) (mm) | ||||||||

| 100 | 200 | 300 | 400 | 500 | 600 | 650 | 700 | 750 | ||||

| Allowable Stress (psi) (kPa) | ||||||||||||

| 16700 | 16700 | 16700 | 15500 | 14400 | 13500 | 13200 | 12900 | 12600 | ||||

| 0.145 | 40 | 1 1/2" | 1629 | 1629 | 1629 | 1512 | 1404 | 1317 | 1287 | 1258 | 1229 | 1.900 |

| 0.200 | 80 | 2303 | 2303 | 2303 | 2138 | 1986 | 1862 | 1821 | 1779 | 1738 | 1.900 | |

| 0.281 | 160 | 3362 | 3362 | 3362 | 3120 | 2899 | 2717 | 2657 | 2597 | 2536 | 1.900 | |

| 0.133 | 40 | 1" | 2205 | 2205 | 2205 | 2047 | 1902 | 1783 | 1743 | 1703 | 1664 | 1.315 |

| 0.179 | 80 | 3061 | 3061 | 3061 | 2841 | 2640 | 2475 | 2420 | 2365 | 2310 | 1.315 | |

| 0.250 | 160 | 4493 | 4493 | 4493 | 4170 | 3874 | 3632 | 3552 | 3471 | 3390 | 1.315 | |

| 0.154 | 40 | 2" | 1371 | 1371 | 1371 | 1272 | 1182 | 1108 | 1083 | 1059 | 1034 | 2.375 |

| 0.218 | 80 | 1985 | 1985 | 1985 | 1843 | 1712 | 1605 | 1569 | 1534 | 1498 | 2.375 | |

| 0.344 | 160 | 3283 | 3283 | 3283 | 3047 | 2831 | 2654 | 2595 | 2536 | 2477 | 2.375 | |

| 0.237 | 40 | 4" | 1102 | 1102 | 1102 | 1023 | 950 | 891 | 871 | 851 | 831 | 4.500 |

| 0.337 | 80 | 1596 | 1596 | 1596 | 1482 | 1377 | 1291 | 1262 | 1233 | 1204 | 4.500 | |

| 0.531 | 160 | 2611 | 2611 | 2611 | 2424 | 2552 | 2111 | 2064 | 2017 | 1970 | 4.500 | |

| 0.216 | 40 | 3" | 1301 | 1301 | 1301 | 1208 | 1122 | 1052 | 1028 | 1005 | 982 | 3.500 |

| 0.300 | 80 | 1844 | 1844 | 1844 | 1712 | 1590 | 1491 | 1458 | 1425 | 1391 | 3.500 | |

| 0.438 | 160 | 2787 | 2787 | 2787 | 2587 | 2403 | 2253 | 2203 | 2153 | 2103 | 3.500 | |

| 0.258 | 40 | 5" | 965 | 965 | 965 | 896 | 832 | 780 | 763 | 746 | 728 | 5.563 |

| 0.375 | 80 | 1428 | 1428 | 1428 | 1325 | 1231 | 1154 | 1129 | 1103 | 1077 | 5.563 | |

| 0.625 | 160 | 2474 | 2474 | 2474 | 2296 | 2133 | 2000 | 1955 | 1911 | 1866 | 5.563 | |

| 0.322 | 40 | 8" | 771 | 771 | 771 | 716 | 665 | 623 | 610 | 596 | 582 | 8.625 |

| 0.500 | 80 | 1218 | 1218 | 1218 | 1131 | 1050 | 985 | 963 | 941 | 919 | 8.625 | |

| 0.906 | 160 | 2298 | 2298 | 2298 | 2133 | 1982 | 1858 | 1817 | 1775 | 1734 | 8.625 | |

| 0.280 | 40 | 6" | 877 | 877 | 877 | 814 | 756 | 709 | 693 | 677 | 661 | 6.625 |

| 0.432 | 80 | 1379 | 1379 | 1379 | 1280 | 1189 | 1115 | 1090 | 1065 | 1040 | 6.625 | |

| 0.719 | 160 | 2382 | 2382 | 2382 | 2211 | 2054 | 1925 | 1883 | 1840 | 1797 | 6.625 | |

| 0.365 | 40 | 10" | 699 | 699 | 699 | 649 | 603 | 565 | 553 | 540 | 528 | 10.750 |

| 0.594 | 80 | 1159 | 1159 | 1159 | 1075 | 999 | 937 | 916 | 895 | 874 | 10.750 | |

| 1.125 | 160 | 2289 | 2289 | 2289 | 2124 | 1974 | 1850 | 1809 | 1768 | 1727 | 10.750 | |

Carbon Steel Pipe Fittings Packing & Marking

Packaging & Delivery

All carbon steel buttweld pipe fittings are securely packaged in wooden cases, pallets or as per customer requirements to ensure safe delivery. We provide complete shipping documentation from mill to customer for a smooth logistics process. Every fitting is marked with specifications, heat number, size and manufacturer details to ensure traceability.

Quality Tests

All our carbon steel pipe fittings undergo 100% quality inspection from raw material selection to final dispatch. We provide NACE 3.1 Certification along with Manufacturer Test Certificates (EN 10204/3.1B), Raw Materials Certificates, 100% Radiography Test Reports and Third-Party Inspection Reports.

Searching for ready stock of Carbon Steel Pipe Fittings in Mumbai?

Industrial Application of Carbon Steel Pipe Fittings

Product Category

Request For Quotation

Do Not Hesitate to Get in Touch With Us. Within Two Business Days, We Will Respond to You. Or Give Us a Call Right Now.

About Neeka Tubes

Neeka tubes is a notable vendor, provider, and exporter of raw materials like springs, tubes, plates, wires,hose clamps and many more.We offer our clients five-star dependable products and administrations with the most extensive level of specialized expertise and business administration during the creation and after deals.

Quick Contact

9, Moti Mansion Building, Ground Floor, 5th Khetwadi Lane,

Mumbai - 400004

Mumbai - 400004