Neeka Tubes is a trusted SS 316L pipe manufacturer in India, providing high-quality seamless pipes for demanding applications. Made from low-carbon austenitic stainless steel, these pipes are perfect for welding and provide excellent resistance to intergranular corrosion. Each ASTM A312 TP316L pipe is designed for tough environments, whether in chemical plants, marine structures, food processing units, or pharmaceutical systems. With high corrosion resistance, heat tolerance up to 870°C and strong mechanical durability, our 316L pipes deliver long-lasting performance. The 316L seamless pipe price per kg changes as per size, quantity, and location. We supply pipes in a wide range of sizes, thicknesses (Schedule 10 to 80) and custom finishes. Each order includes Mill Test Certificates (EN 10204 3.1), optional third-party inspections and reliable global shipping. As a leading supplier of SS 316L pipes, we guarantee constant quality, and on-time delivery around the world.

SS 316L Seamless Pipe, 316L Stainless Steel Pipe, SS 316L Pipe Suppliers, 316L Stainless Steel Pipe Price, SS UNS S31603 Seamless Pipes, SUS 316L Seamless Pipes, SS 316L Cold Drawn Pipes

- Pipes

- Stainless Steel Pipes

- Titanium Pipes

- Tubing

- Sheets and Plates

- Fasteners

- Pipe Fittings

- Round Bar

- Hex Bars

- Square Bars

- Wire

- Flanges

- Other Fittings

- Springs

Request For Quotation

What Is ASTM A312 TP316L Seamless Pipe?

ASTM A312 TP316L seamless pipe is a low-carbon, austenitic stainless steel pipe built for high-pressure and corrosive environments. Made to ASTM A312 standards, it performs reliably in heat, moisture, and chemical-rich conditions. The added 2–3% molybdenum boosts its ability to resist pitting and chloride attack, making it ideal for marine and chemical use. Also known as UNS S31603 prevents, sensitization during welding which keeps the pipe strong and corrosion resistant after fabrication. The seamless construction assures uniform wall thickness, tight tolerances, and leak-proof strength. As a trusted SS 316L pipe manufacturer in India, we recommend 316L pipe when you need a durable, clean, and high-performance molybdenum-grade option.

Benefits of Stainless Steel 316L Seamless Pipe

Stronger Resistance in Harsh Environments

The added molybdenum boosts 316L pipe corrosion resistance, especially against chlorides, saltwater, and aggressive chemicals.

Performs Under Pressure

With high tensile strength, SS 316L seamless pipe handles pressure and mechanical stress without cracking or deforming.

Safe for Weld-Heavy Projects

Its low carbon content minimizes the risk of sensitization after welding, making it ideal for boilers and pressure systems.

Clean, Smooth Inner Surface

The seamless design ensures a smooth bore, which reduces friction loss and contributes to hygiene in pharmaceutical and food lines.

Low Maintenance, Long Service

Stainless steel 316L pipe resists corrosion and scaling over time, cutting down on maintenance, and replacement.

Fits a Range of Uses

Available in multiple diameters and wall thicknesses, SS 316L pipe fits everywhere from industrial systems to marine applications.

These SS 316L seamless pipe benefits make it a top choice for high-temperature pipe systems, that demand long-lasting reliability.

SS 316L vs SS 304 vs SS 304L – Grade Comparison

SS 304, SS 304L, and SS 316L seamless pipes might seem similar, but their properties serve different industries. Here’s how these grades compare where it matters:

Corrosion Resistance in Chloride Environments

Stainless steel 316L seamless pipe contains molybdenum, which gives it superior resistance to chloride attack. This makes it ideal for coastal, marine, or chemical processing setups. Neither SS 304 (UNS S30400) nor SS 304L (UNS S30403) can match this performance under chloride-rich exposure.

Weld Zone Protection

Both Stainless steel 304L pipe and SS 316L have low carbon content. That limits carbide precipitation in the heat-affected zone during welding. In contrast, standard 304 stainless steel is more prone to weld decay if not properly treated.

Use-Case Suitability

SS 304 seamless pipe works well in indoor, non-aggressive settings like food processing, furniture, and water systems. Stainless steel 304L seamless pipe is ideal for welding applications with little chloride exposure. Stainless steel 316L seamless pipe is suitable for environments with high purity, corrosiveness or pharmaceutical grade.

Cost & Market Availability

SS 304 is the most affordable and widely available option. SSS 304L is significantly more expensive because of its improved weldability. The premium choice, SS 316L (UNS S31603), is more expensive but often required in extremely corrosive or regulated systems.

Most Common Types of Stainless Steel 316L Seamless Pipe

SS 316l Seamless Pipe

316l SS Round Pipe

SS 316l Schedule 5S Pipe

SS 316l Polished Pipe

SS 316l Schedule 40 Seamless Pipe

316l Stainless Steel Thin Wall Pipe

Stainless Steel 316l Custom Pipe

Stainless Steel 316l Cold Drawn Seamless Pipe

Stainless Steel 316L Seamless Pipe Specifications

This section lists key specifications of SS 316L seamless pipes, including standards, size range, form, and finish options for industrial use.

| Specifications | ASTM A312 / ASTM SA312 |

| Dimensions | ASTM, ASME and API |

| Range | 6NB to 1200NB |

| Outer Diameter | 1/8″ NPS to 12″ NPS |

| Thickness | 0.6 mm to 12.7 mm |

| Schedules | SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS |

| Length | Single Random, Double Random & Cut Length |

| Types | Round, Square, Rectangle, Hydraulic, Honed Tubes |

| End | Plain End, Beveled End |

316L Stainless Steel Seamless Pipe Chemical Composition

The detailed chemical makeup of SS 316L pipes, showing exact percentages of chromium, nickel, molybdenum, and other elements.

| Grade | Ni | N | Cr | C | Si | Mn | P | S | Mo |

| SS 316L | 10 – 14 | 0.10 max | 16 – 18 | 0.08 max | 0.75 max | 2 max | 0.045 max | 0.030 max | 2.00 – 3.00 |

Mechanical Properties of SS 316L Seamless Pipe

This mechanical strength of 316L pipes includes tensile strength, yield strength, elongation and hardness values.

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50mm) min | Hardness |

| SS 316L | 485 | 170 | 40 | Rockwell B (HR B) max 95, Brinell (HB) max 217 |

Equivalent Grades For 316L Stainless Steel Seamless Pipe

The table shows global grade equivalents for SS 316L, allowing users to match international standards like as UNS, EN, and JIS codes.

| STANDARD | UNS | WERKSTOFF NR. | JIS | AFNOR | BS | GOST | EN |

| SS 316L | S31603 | 1.4404 / 1.4435 | SUS 316L | Z3CND17‐11‐02 / Z3CND18‐14‐03 | 316S11 / 316S13 | 03Ch17N14M3 / 03Ch17N14M2 | X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

Contact Neeka tubes today for a best offer & competitive quotation Of Stainless Steel 316L Seamless Pipes

Please Call on +91 7700067892 or drop an E-Mail : sales@neekatubes.net

Stainless Steel 316L Seamless Pipe Dimensions In MM

The standard pipe dimensions in millimeters, covering outer diameter, wall thickness and approximate weight per meter.

| Outside Diameter | Qty/B | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 1.2 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Inches | mm | Lgh | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs | Kgs |

| 3/8″ | 9.5 | 100 | 0.81 | 0.94 | 1.06 | 1.18 | 1.29 | 1.51 | 1.82 | |||||

| 1/2″ | 12.7 | 100 | 1.10 | 1.28 | 1.45 | 1.61 | 1.78 | 2.10 | 2.55 | |||||

| 5/8″ | 15.9 | 100 | 1.39 | 1.62 | 1.84 | 2.05 | 2.26 | 2.68 | 3.28 | |||||

| 3/4″ | 19.1 | 100 | 1.69 | 1.96 | 2.22 | 2.49 | 2.75 | 3.26 | 4.01 | |||||

| 7/8″ | 22.2 | 100 | 1.97 | 2.29 | 2.60 | 2.91 | 3.22 | 3.83 | 4.72 | |||||

| 1″ | 25.4 | 100 | 2.26 | 2.63 | 2.99 | 3.35 | 3.71 | 4.41 | 5.45 | |||||

| 11/8″ | 28.6 | 50 | 2.55 | 2.97 | 3.38 | 3.79 | 4.19 | 5.00 | 6.18 | |||||

| 11/4″ | 31.8 | 50 | 2.84 | 3.31 | 3.77 | 4.23 | 4.68 | 5.58 | 6.91 | |||||

| 11/2″ | 38.1 | 50 | 3.42 | 3.98 | 4.53 | 5.09 | 5.64 | 6.73 | 8.34 | |||||

| 15/8″ | 41.3 | 50 | 3.71 | 4.32 | 4.92 | 5.52 | 6.12 | 7.31 | 9.07 | |||||

| 13/4″ | 44.5 | 50 | 4.00 | 4.66 | 5.31 | 5.96 | 6.61 | 7.90 | 9.80 | |||||

| 2″ | 50.8 | 10 | 6.08 | 6.82 | 7.57 | 9.04 | 11.24 | 14.83 | 21.79 | |||||

| 21/2″ | 63.5 | 10 | 7.62 | 8.56 | 9.50 | 11.36 | 14.13 | 18.69 | 27.58 | |||||

| 3″ | 76.2 | 10 | 9.17 | 10.30 | 11.43 | 13.68 | 17.03 | 22.55 | 33.37 | 43.88 | ||||

| 31/2″ | 88.9 | 10 | 10.71 | 12.03 | 13.36 | 15.99 | 19.92 | 26.41 | 39.16 | 51.60 | ||||

| 4″ | 101.6 | 10 | 18.31 | 22.82 | 30.27 | 44.95 | 59.32 | 73.39 | 87.16 | |||||

| 5″ | 127 | 10 | ||||||||||||

| 6″ | 152.4 | 10 | ||||||||||||

SS 316 Seamless Pipe Thickness Chart

This chart lists available thickness options for SS 316L seamless pipes, helping buyers choose the right wall thickness for their application.

| Outside Diamter, OD (in mm) | Wall Thickness, WT (in mm) |

|---|---|

| 6mm – 630mm | 0.5mm-30mm |

| 12.7mm* 12.7mm to 300mm* 300mm | 0.5mm-30mm |

| 10*20mm to 100*200mm | 0.5mm-30mm |

| 6mm to 630mm | 0.5mm-30mm |

| 12.7mm to 250mm | 0.5mm-30mm |

| 16mm to 85mm | 0.5mm-3.0mm |

| 13mm to 85mm | 0.5mm-2.0mm |

| 20mm to 200mm | 0.5mm-2.0mm |

| 22mm*0.7mm to 108mm*2.0mm | 0.5mm-2.0mm |

| 12.5mm to 203.2mm | 1.0mm – 5mm |

| 0.28mm to 10mm | 0.08mm – 1.2mm |

| 6mm to 430mm | 0.8mm – 30mm |

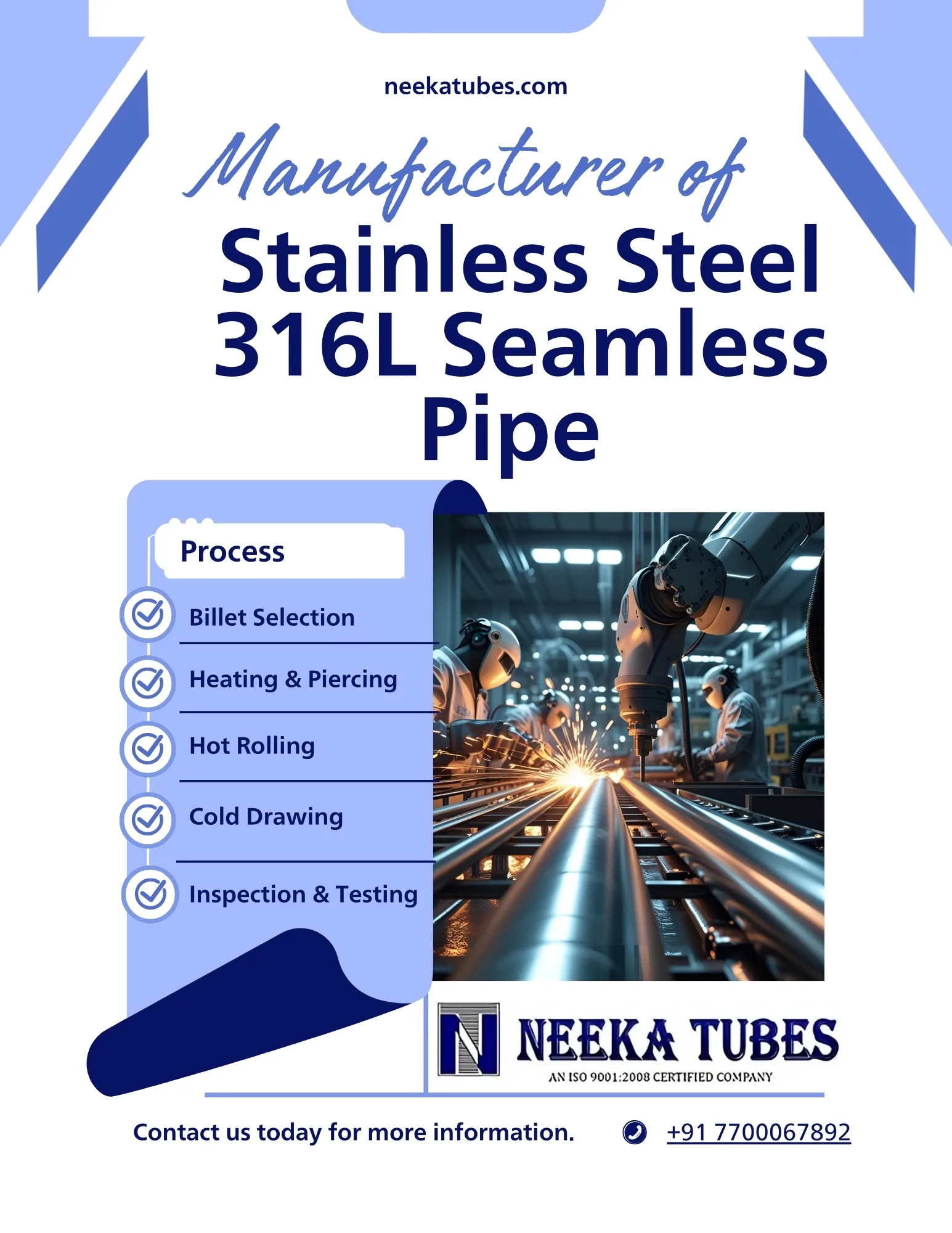

Manufacturing Process for SS 316L Seamless Pipe

The manufacturing of SS 316L seamless pipes involves precise hot working methods and quality checks to deliver pipes that perform well under pressure and in corrosive environments.

- Billet Selection – First step is to select high-quality SS 316L billets that are sourced to ensure purity and consistent mechanical properties.

- Heating & Piercing – Then the billets are uniformly heated and pierced through a mandrel to create a hollow tube structure.

- Hot Rolling/Extrusion: The pierced shell is hot rolled or extruded to achieve the appropriate outer diameter and wall thickness.

- Cold Drawing (if needed) – Pipes are redrawn at room temperature to improve surface finish and maintain tighter tolerances.

- Solution Annealing – Heat treatment is applied to restore corrosion resistance and relieve internal stress from forming.

- Straightening & Finishing – Pipes are straightened, trimmed, and cleaned for smooth appearance and accurate length.

- Final Inspection & Testing – Each pipe undergoes hydro testing, NDT, and dimensional checks to meet strict quality standards.

The SS 316L seamless pipe manufacturing process ensures durable, precise, and corrosion-resistant pipes for demanding industrial use.

Heat & Corrosion Resistance Ratings

Stainless steel 316L seamless pipe offers excellent resistance to heat and corrosion, making it a strong choice for harsh environments. At temperatures as high as 870°C, it is resistant to oxidation and scaling, which makes it suitable for high-temperature service and thermal systems. Its low carbon content (L grade), helps prevent intergranular corrosion after welding, which is critical in systems that require clean welds and long-term durability. This alloy performs well in chloride-rich situations, and holds up against acids in chemical processing setups. Its proven reliability in chemical, marine and pharmaceutical industries reflects its broad corrosion resistance and stable composition. It also stands up to indoor and outdoor elements like industrial gases and moisture, keeping its structure and strength over time. Whether under high pressure or temperature shifts, SS 316L pipe performance remains consistent, making it a trusted material for heat exchangers, reactors, and pressurized systems. This combination of 316L pipe heat resistant protection provides long-term use under even the harshest conditions.

Testing and Certifications for Stainless Steel 316L Seamless Pipe

Every SS 316L seamless pipe goes through strict quality checks to ensure performance, and reliability. We do hydrostatic pressure testing to ensure there is no leakage under pressure. Non-destructive testing such as ultrasonic or eddy current, assists in detecting interior problems, without destroying the pipe. To confirm the right material, we do PMI (Positive Material Identification) to verify the alloy grade. Pipes are also checked with mechanical tests for tensile strength, hardness, and flattening. After welding, we perform IGC tests to ensure corrosion resistance at grain boundaries. Each batch contains a Mill Test Certificate (EN 10204 3.1) with complete chemical and mechanical data. If needed, we also arrange third-party inspections through agencies like TUV, SGS, or BV. Every test aligns with ASTM A312 pipe certifications to meet the highest quality standards. Our SS 316L pipe inspection procedures are designed to give you full confidence in every pipe we ship.

Packaging & Delivery – Domestic & Export

Each stainless steel 316L seamless pipe is carefully packed to avoid damage, corrosion, and moisture, during storage and transportation. We employ ISPM-15 approved wood crates, HDPE-wrapped bundles, and plastic end caps to protect the pipes from scratches and contamination. All packing meets seaworthy standards to keep the pipes undamaged during long-distance transportation. For domestic delivery, we assure quick dispatch, proper layering, and clear barcode or tag labeling to facilitate handling and tracking. Every order comes with complete paperwork, such as Mill Test Certificates (EN 10204 3.1 or 3.2), heat number markings and detailed specification tags. We partner with trusted logistics providers to make sure deliveries arrive safely and on time whether across India or to global destinations.

Why Choose Neeka Tubes for Stainless Steel 316L Seamless Pipes

Neeka Tubes is a trusted SS 316L seamless pipe supplier in India. We are known for certified quality, timely delivery, and export-ready solutions tailored to your industry needs.

- Trusted SS 316L seamless pipe manufacturer in India with global export capabilities

- Supplies ASTM A312 TP316L pipe with Mill Test Certificates (EN 10204 3.1)

- We maintain ready stock in a wide range of sizes, schedules, and surface finishes

- Provides unique lengths and cut-to-size alternatives based on your project requirements.

- Fast dispatch and reliable delivery across India and international locations

- Follows tight dimensional tolerances with strict in-house quality checks

- Our team packs every order securely using HDPE wrapping, plastic end caps, and ISPM-15 wooden crates

- Handles both bulk and small quantity orders with equal care

- We are also known for responsive customer service and timely technical help.

Searching for Ready stock of Stainless Steel 316L Seamless Pipes in Mumbai?

Applications of SS 316L Seamless Pipes

Stainless steel 316L seamless pipes are utilized in industries requiring exceptional corrosion resistance, strength and hygiene. Their performance in aggressive and sanitary environments makes them a top choice across sectors.

- Chemical Processing – These pipes are designed to handle severe acids, alkalis, and corrosive fluids without degrading or contaminating the system.

- Pharmaceutical & Food Industries – SS 316L’s non-reactivity and ease of sterilization, making it perfect for cleanrooms, processing lines, and hygienic situations where contamination is a concern.

- Marine Applications – Known for its resistance to saltwater and moisture, SS 316L performs well in marine structures, piping, and underwater equipment exposed to harsh coastal and offshore conditions.

- Oil & Gas – These pipes are capable of withstanding high temperatures and pressures, which are used in drilling, exploring, and refining processes. They’re a safe and durable choice for pipelines and processing units.

- Heat Exchangers & Boilers – SS 316L resists scaling and oxidation at elevated temperatures, making it suitable for systems where heat transfer efficiency and metal stability are critical.

- Power Plants and Refineries – The alloy is perfect for power generation and refining units that operate continuously under heavy loads because it is resistant to temperature cycling, vibration and stress.

- These uses for stainless steel 316L pipes show their significance in terms of safety, hygiene, and long-term durability in difficult conditions.

FAQ

How is 316L different from 316 seamless pipe?

316L has less carbon than 316, making it more corrosion resistant after welding. Both have equal mechanical strength and seamless structure.

What are the typical sizes and schedules of SS 316L seamless pipe?

Common sizes range from 1/8″ to 24″ NB, with schedules from SCH 5S to SCH 160 and even XXS.

What is the maximum operating pressure of SS 316L seamless pipe?

Depends on size and schedule. For example, 1″ SCH 80 pipe can handle up to 5,100 psi at room temperature. Always refer to ASME B31.3 or manufacturer specs.

How does SS 316L seamless pipe compare with 304L?

316L has added molybdenum, offering better resistance to pitting and corrosion, especially in chloride or marine environments. It’s more durable but slightly more expensive than 304L.

About Neeka Tubes

Quick Contact

Mumbai - 400004